Protect your pressurized assets against internal corrosion

STOP USING TRADITIONAL CORROSION MONITORING METHODS

Prone to human error

Thousands of locations

Difficulty of access

Non-digitized data

START USING SMART CORROSION MONITORING EQUIPMENT

MICROPIMS INTRINSICALLY SAFE WIRELESS ULTRASONIC SENSORS

WAND UT SYSTEM

HotSense™ ultrasonic transducers.

Dakota Ultrasonics

Artio device

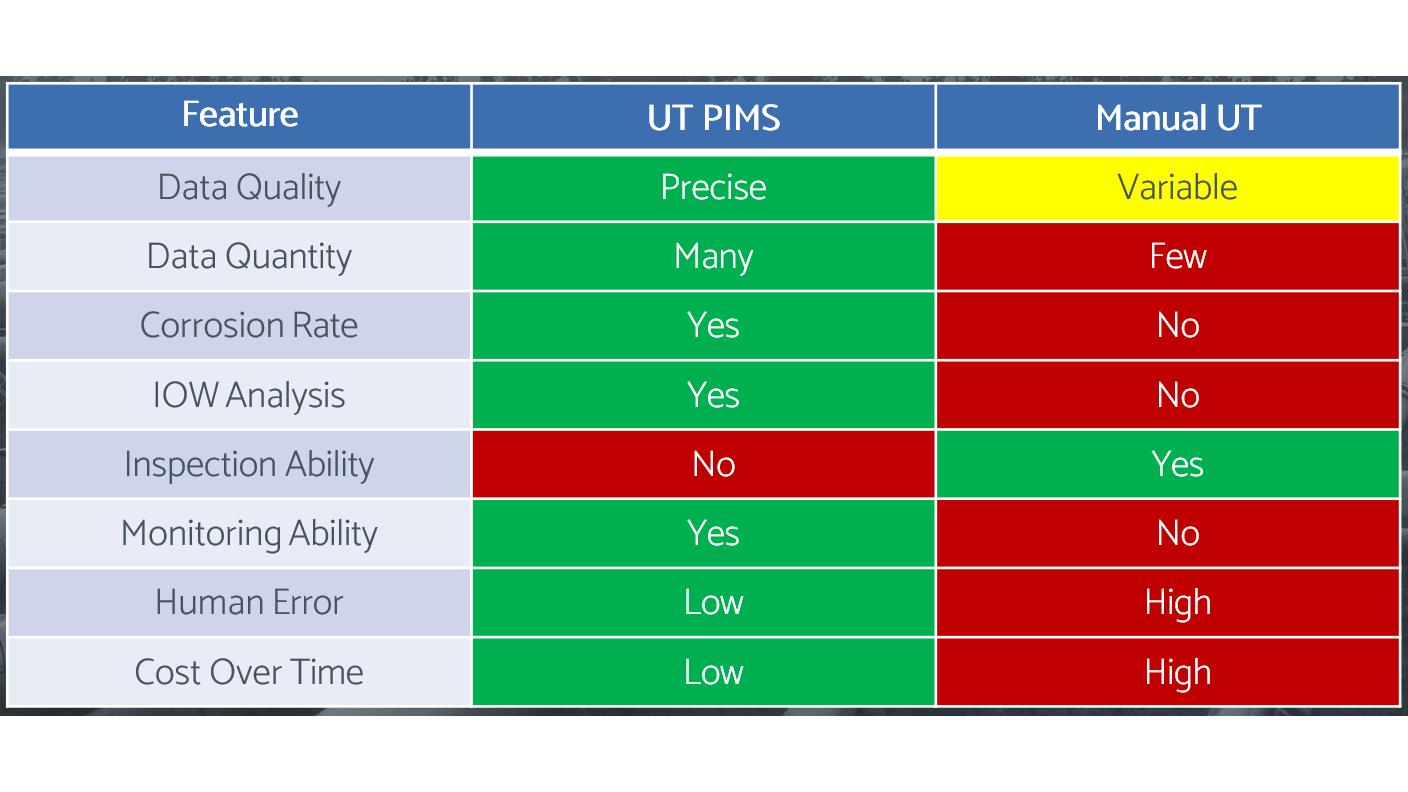

Our corrosion monitoring products can excel manual UT methods:

We're experts in corrosion engineering

Our Services

Corrosion management

NDT Inspections

Remote visual inspections

By implementing our solutions, your company can save money from:

Reduced NDT inspections

While complete elimination is unlikely, a potential 20% reduction in NDT inspections could save money after our solutions are implemented.

Reduced Maintenance & Repair Costs

Proactive maintenance based on real-time data can potentially reduce unplanned maintenance and repair costs. (Quantifying these savings requires data on historical maintenance costs and potential reduction due to early detection.)

Extended Asset Life

Early detection and prevention of corrosion could potentially extend the lifespan of the your company assets beyond their designed lifespan, delaying replacement cost.

Improved safety

Early detection of corrosion minimizes risks of leaks, equipment failure, and potential accidents.

Improve your assets integrity

Let us support you with cost-effective selection and application of high quality products to manage your asset’s integrity.